Business Building: Keep Your Profit Builder Wheel Spinning!

Words: George Hedley

George Hedley

The number one challenge many contractors face is making less money than they wanted at bid time or what I call profit shrinkage or profit margin fade. This recurring problem occurs when final construction job cost comes in higher than their bid or contract project budget. In other words, the final completed job profit comes in lower than estimated, hoped for, or projected at bid time. As a construction company business coach, I see numerous contractor income statements or P & Ls every year. I often hear company owners tell me for example, they bid using a fifteen percent mark-up for overhead and ten percent for profit. But after studying their year-end profit and loss statement, they only end up with a total of twenty percent gross profit. I ask them what happened to the other five percent. Was it lost and how did it disappear? They generally don’t know why their profit wheel caused money to fly off the wheel or how they reduced their bottom-line margin.

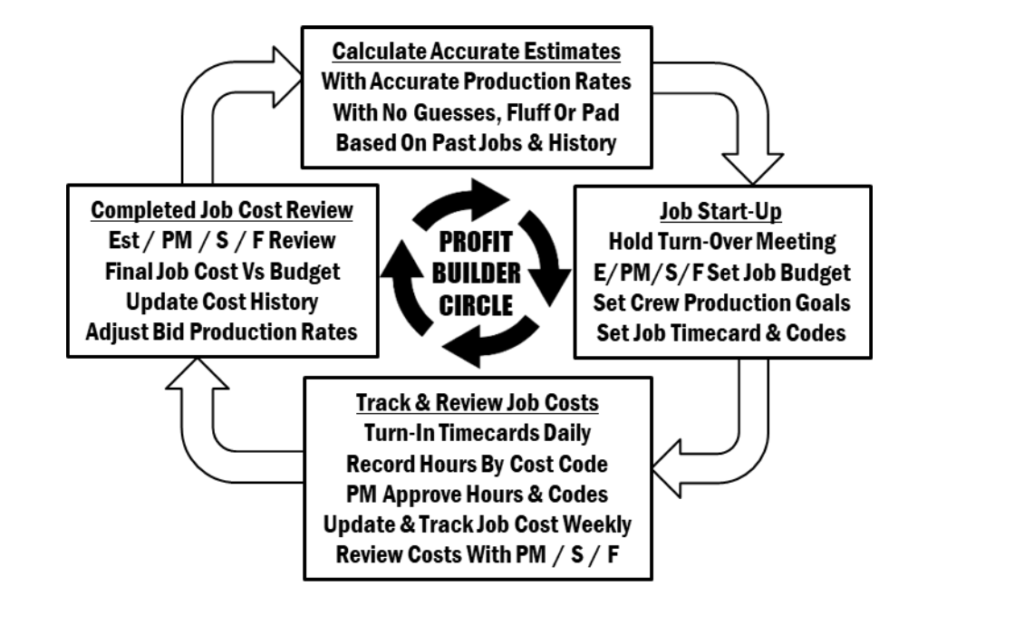

What causes your Profit Builder Circle to stop spinning?

Estimators bids jobs using their standard company production crew rates for labor and equipment. Then on a regular basis, completed jobs actually often cost more than the bid budgets. Why? Profit margin loss or shrinkage can occur for many reasons including:

- The estimator uses what I call the ‘blind man method’ of bidding. This occurs when he shuts his eyes and guesses how many hours the crew will take to complete a task.

- The estimator uses what I call the ‘mystery method’ of bidding. This occurs when he uses a standard square foot or lineal foot price to bid work. For example, to build and pour concrete sidewalks, he estimates $5.75 per square foot. Or to dig and install 6 inch sewer main four feet deep, he estimates $25.00 per lineal foot for total labor, equipment and material versus calculating the exact production labor, equipment and material required.

- The estimator uses a percentage adder factor to cover required supervision, general conditions, clean-up, and mobilization on bids. For example, on a $100,000 job, he might add 5% to pay for these costs, which may or may not be the right amount to cover all these expenses depending on real jobsite conditions including site layout, schedule, location of utilities, etc..

- The estimator misses several items or project components required to complete the scope of work contracted for things such as testing, blocking, miscellaneous steel supports, traffic control, surveying, backfill, additional move-ins, asphalt repair, or poor supervision.

- The estimator underestimates the schedule or time required and the overall project takes longer to build than estimated. Or field crews go slower than the time estimated to complete the work, causing the overall job costs to increase higher than anticipated.

- Field crews were not very efficient which can be caused by many factors including: poor supervision, little or no pre-project planning, several unanticipated additional move-ins, lack of proper scheduling, bad weather, or other factors that occur out in the field.

- The crew leaves the job before they are 100% complete to get to another project. Then they have to come back several times to finish their work and the punch-list.

And now, the top 3 reasons which actually cause your profit wheel to stop spinning:

- The estimator uses inaccurate, out of date, too low, or too optimistic production rates to calculate the total labor or equipment required to complete the work.

- The field foreman wasn’t ever given the project labor production budget or goals for crew hours. Then he wasn’t given any updated weekly job cost status reports throughout the project to see if the crew was on budget or needs to make adjustments. And the foreman wasn’t held accountable to meet the job goals for labor and equipment hours.

- The estimator didn’t go back after projects were completed to verify the labor and equipment production bid rates used were accurate versus the final job costs. And the bid rates were not adjusted properly to make sure they were right to use for future bids.

Steps To Keep Your Profit-Builder Circle Spinning!

In order to maintain your profit margins and ensure all projects hit the estimated job budgets for labor and equipment, contractors have to invest people, time, and money to implement and monitor the systems and structure required to keep the profit wheel continually spinning round and round.

- It starts with an accurate budget based on real field actual costs broken down by cost code and hours required to do the work based on a cost history.

- Then the project team holds a pre-job start-up meeting to set the budget, crew production hours goals for each phase or cost code, and design a time card to track the hours for each task.

- Next the crew hours are accurately tracked daily for each job and cost code. These hours are tabulated and reviewed by the foreman, superintendent and project manager every Monday to see if they are on budget.

- And then at job completion, the foreman, superintendent and estimator review the final hours versus the budget by cost code and make any adjustments required for their cost history to use on their next bid or estimate.

Step 1 - Estimate the right number of crew hours.

Prepare your construction estimates using unit prices for labor and equipment production based on actual cost history of the quantity of items installed per hour. For example: it generally takes an average of one man-hour to dig and plant a fifteen gallon tree, or install and grout ten masonry blocks, or install three downlights in a ceiling, or dig one hundred lineal feet of sewer trench. After the estimator completes the quantity take-off and estimates the number of man-hours to complete the project based on accurate cost history production rates, he should then meet with a field superintendent or foreman to discuss and verify the estimate seems right. Together they should agree on the total hours required to do all the work before the bid is finished and turned in.

Step 2 – Pre-plan to hit the budget.

After bid are submitted and your company is awarded a contract, the project team meets to plan the job, determine the number of production hours required versus the budget, and then what the crew will need to do to hit the goals. Get the estimator together with the project manager, superintendent, and foreman to review the estimated budget in a pre-construction turn-over or hand-off meeting. This is the time to review the scope of work, draft a detailed field work plan, determine the right crew size to be efficient, discuss any omissions or holes in the bid, and then make the necessary adjustments to the project budget. In other words, take the bid estimate and reformulate it to match reality and what the team commits to accomplish.

Now combine or adjust cost codes to allow the field to track their time in a simpler version of the budget. Make sure timecards match the actual job budget, and are setup to allow for easy time card coding and tracking, and job costs are updated and reviewed weekly. Also, break down the budget by job phases if appropriate for longer duration projects. This process will allow your team to know their crew hour production goals for the tasks required to complete the job for each phase.

Step 3 - Build the job on budget.

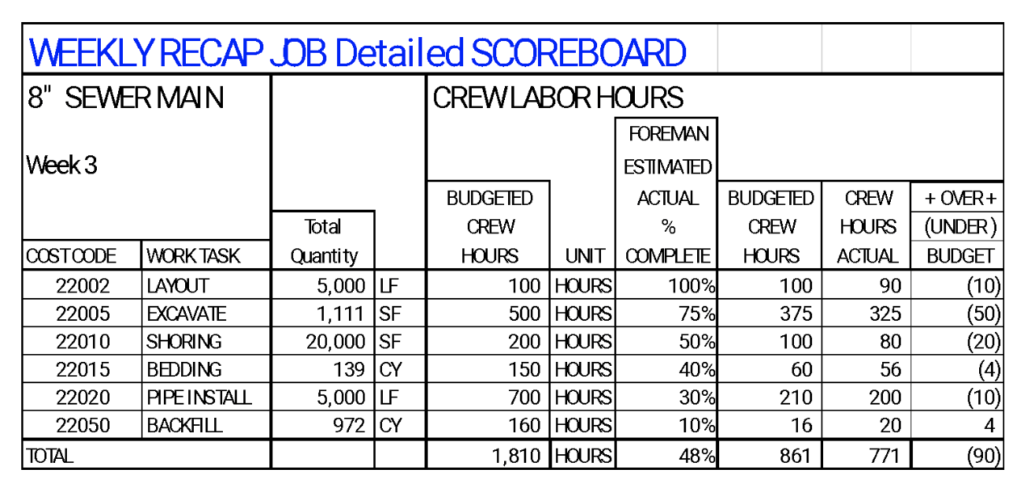

With clear labor hour and equipment targets and goals for the crew to achieve, the field can now keep track of their progress against the budget. Have the field complete their timecards coded properly against the right cost codes and turn in their time daily. At week end, have the foreman also turn in the quantity of work completed for every task cost code. By Monday morning, have your job cost engineer calculate the budget versus actual time spent against each cost code on every job. Then on Monday, the project manager must review the weekly progress versus the budget and communicate the actual results with the superintendent and foreman.

This process allows the field to be aware of their progress versus the budget and make any adjustments necessary to keep their jobs on budget. Without this process the field has no clue where they are and what they need to do to meet the budget.

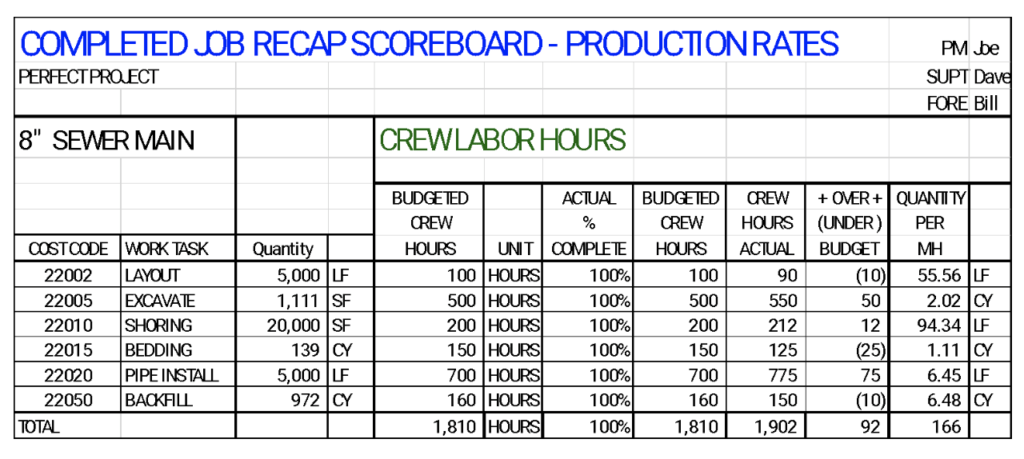

Step 4 - Adjust your estimating cost history.

The final step to keep the profit wheel spinning is to review the final job costs after projects are completed to determine if the estimate and budget were accurate. Have the estimator meet with the project manager and field foreman or superintendent to review the final job costs versus the bid estimate. Look for reasons the final job costs were different than the budget and determine adjustments required to bid future projects accurately. Have the estimator make notes to help remember why this job cost more or less than the original bid. And then update the companywide estimating cost history library for future bids.

Keeping the profit wheel spinning takes a commitment to plan, hold meetings, calculate your job costs every week, keep your field foreman informed, and dedicate the time required to keep the wheel spinning. To help set up a job cost tracking system, email gh@hardhatpresentations.com to get a copy of George’s field production scorecard template. When you do what you know you need to do to develop accurate cost estimates, your profit margin will stop fading and you’ll start making more money.

About the Author

George Hedley CPBC is a certified professional construction BIZCOACH and popular industry speaker. He helps contractors grow, make more profit, build management teams, improve field production, and get their businesses to work for them. He is the best-selling author of “Get Your Construction Business To Always Make A Profit!” available on Amazon.com. To start a BIZCOACH program, sign-up for his newsletter, attend a webinar or workshop, or get a discount at HardhatBIZSCHOOL.com online university for contractors, visit HardhatBIZCOACH.com or e-mail GH@HardhatBIZCOACH.com.

Email: GH@HardhatBizcoach.com

Website: www.hardhatbizcoach.com