Thinking Of Buying Used Mast Climbers? Read This First.

Words: Chick Hatton

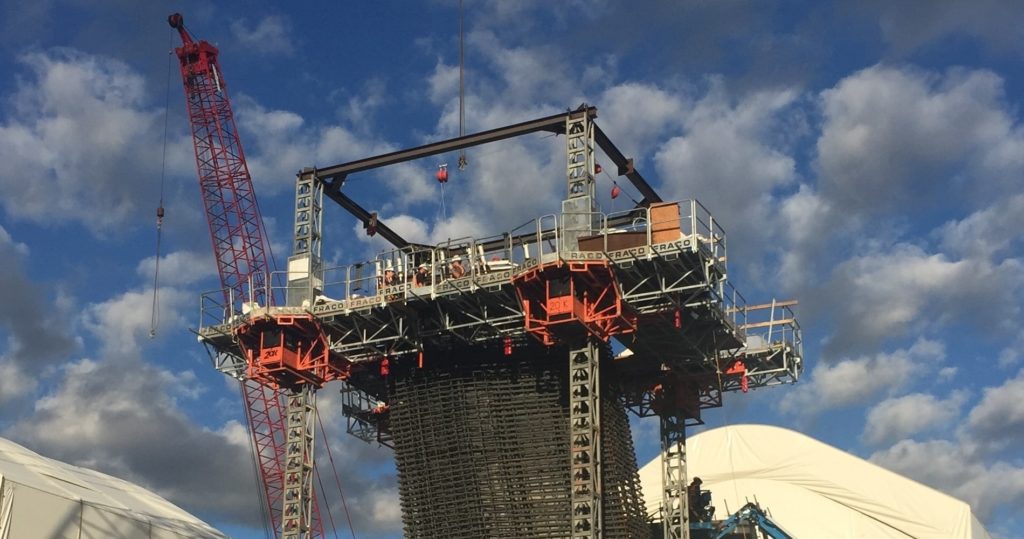

Words: Chick Hatton, Access Specialist for FRACO Products

Photos: Fraco Products

Buying used mast climbers can be a complicated process, because there will always be that diamond in the rough or those deals that sound too good to be true. In either case, having knowledge on the equipment you are buying will help you make better decisions!

Questions like these are important:

- How many hours are on the unit?

- What year was the unit manufactured?

- Is the manufacturer still producing the unit?

- Has it passed inspection?

- Who used this equipment (what trade)?

- Where can you purchase additional parts should you need any?

Let’s go over them.

1. Hours on the unit.

The year of the unit does not automatically correlate with the hours of use, which is why it’s important to check the hour gage. An older unit can offer fewer used hours than a newer one. This could be a very important factor depending on the unit and the type of unit it is.

2. What is the year of the equipment?

Most equipment will have a serial number, and that number can help you determine what year the unit was manufactured. The year of the unit should play a large part in your decision-making. Are there any updates for the unit you are considering and if so, what is that cost? How many more years will you get out of this purchase? Is the equipment galvanized or painted?

3. Does the manufacturer still produce the unit or still make parts for the unit?

If the manufacturer is no longer producing the unit, it may be tough to purchase parts should something break down or if you need support on the equipment from the manufacturer or dealer.

4. Has it passed inspection? THIS IS VERY IMPORTANT.

Today, there are standards for testing the equipment. If the equipment has not passed or has not been tested, you may be purchasing something that can’t be certified or even used onsite. This equipment, depending on the inspection, may only have a few years left of usage. And if the equipment is marginal, what will be the cost of repair to pass inspection?

5. Who used the equipment before me? In what trade was it used?

If the equipment was used by masons, chances are the equipment has been stressed as this trade can be hard on equipment. Did they wash the unit after wash down? Did they store units properly? Was maintenance performed after each project?

Finally, another question to consider is the type of training that will be needed for your team to use the equipment and the cost and availability of that training.

When considering purchasing used equipment, don’t hesitate to contact the manufacturer directly. Don’t be afraid to see if the manufacturer or its dealers have any used units for sale and ask them if they are aware that their equipment is being sold. These people can be your allies: they know the equipment and can be a great resource to help you make the correct choice. They can also quote new equipment equal to what the used equipment may be, so you can do some price comparison.

When buying directly with the manufacturer, you may also be able to purchase equipment with a warranty: most manufacturers will offer a 6-month warranty on used equipment. And then, you can negotiate training with the final asking price…

Buying on the market can be tricky for sure, but with this knowledge, you should be able to make a financially sound decision on your used Mast Climber purchase!

Hope this helps you and don’t hesitate if you have any questions; I’d love to help you find the best equipment possible!