Restoring and Preserving the Huerfano County Courthouse

Words: Cass Stern

Words: Cassandra Stern

Photos: Mountain Masonry

Located in Walsenburg, Colorado in Huerfano County, there is a historic courthouse that has been standing since 1904, with a standalone jail that has been there since 1896. Registered with the National Register of Historic Places in April 1973, the jail is renowned for having held Bob Ford, the killer of infamous outlaw Jesse James. While masonry buildings like this one continue to stand the test of time, the elements can be cruel and unusual in their treatment of even the best-constructed building. Over the years, whipping winds, harsh rainstorms, and heavy snowfall have taken their toll on the integrity of this beautiful building. It was only a matter of time before an experienced mason needed to step in and take the reins of this massive restoration project.

Enter Michael Madone of Mountain Masonry. Madone is a third-generation mason who has been involved in the family business his entire life. His background in architecture and environmental design, along with years of experience in residential and commercial projects to historical restoration and preservation work, have helped make Mountain Masonry an excellent candidate to tackle this project.

Their involvement with Owens Architects was relatively straightforward having previously worked with them and who were already involved with the Huerfano County Courthouse restoration project. “We secured the job, we had a plan, and when we finally got a scaffold built and I climbed to the top. I stood right next to it face-to-face, and thought ‘wow, what have I gotten myself into,’” Madone asked himself.

With most of the funding for the restoration project being sourced through the Colorado State Historic Fund, Madone’s plan is to move forward with one elevation each year until the courthouse is complete, with the hopes of moving on to the restoration of the jailhouse afterward. “I’m hoping that we’re working on this project for the next 4-6 years,” states Madone.

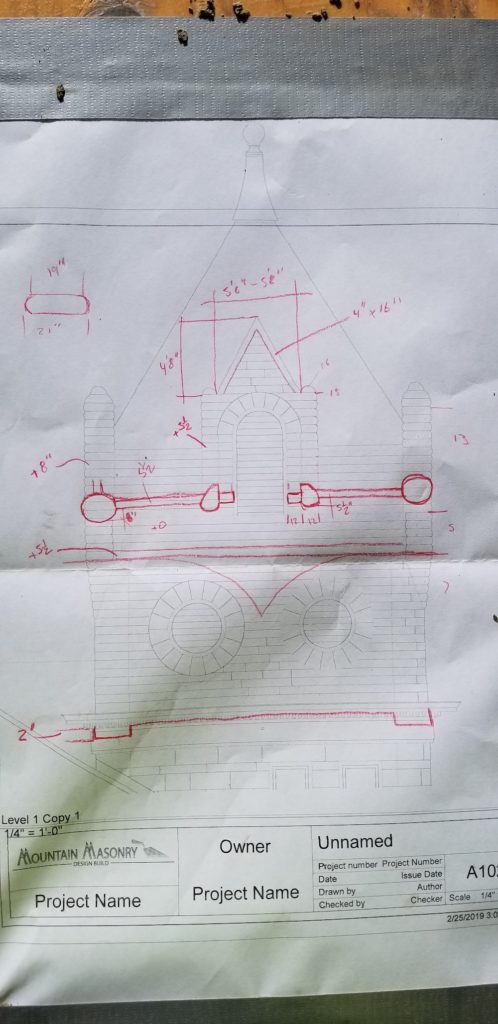

When it comes to historical restoration and preservation projects, every step must be completed as efficiently as possible without sacrificing accuracy. This means that the planning stages are of the utmost importance, as a solid foundational approach lays the groundwork for a successful outcome. When the time came to sit down and start planning Phase One of the Huerfano Courthouse restoration project, Madone immediately went back to his roots as an architecture student. Having successfully utilized Revit, CAD, and BIM on previous masonry projects, he was able to combine this technology with his experience and apply it to the current job.

“I was excited to be able to use it,” states Madone. In most masonry restoration and historic preservation projects, contractors typically want to preserve as much of the original material as possible, but the courthouse tower is predominantly made of soft sandstone. “The geometry of the upper towers especially made it weather pretty badly, and was in such bad condition, the plan was to remove it and replace it”, said Madone. This team had a plan, “we got scaffold built, we got up there and we slowly took it apart piece by piece, and slowly modeled it piece by piece in the computer creating this 3D model.”

Using this model, they were able to get precise measurements and analysis to draft drawings on every single piece of material. “There are 45 custom shapes on this project, and once they were all done we had a kit of parts and were able to reconstruct it,” Madone explains. As there was a significant amount of material that needed to be removed and replaced on the upper tower, matching the replacement stone to the existing stone was an important process as well.

Madone chose to work with Quarra Stone Company, a quarry in Madison, Wisconsin when it came to sourcing materials. With their help, they were able to select a replacement material that was “a very close match. It’s a much better stone, as in it’s going to weather much better, and is not as soft, but it’s a sandstone and the color is very close.” A month after he sent the drawings and 3D renderings to Quarra Stone, they had the pieces they needed to get started in hand.

“There were minimal chiseling and reshaping, and once we had the pieces put together, everything fit really nicely.” At this stage, they were also able to determine that the majority of the pieces on the upper 20 ft. of the courthouse were subject to the most wear. While much of the main building’s materials can be salvaged, on “the upper tower, the exterior is roughly six inches of material that needed to be removed, and it’s got another 12-16 inch rubble back up that stayed,” said Madone.

In Phase One, Madone and his team started at the top of the 40-ft. tower. As their largest telehandler onsite maxes out at 40 ft., the crew is using an electric hoist to raise and lower materials from the ground to the worksite. The height itself, as well as determining how to transport materials smoothly and safely, has presented somewhat of a challenge for the masons working on this project. Especially when it comes to removing stones that range from 30-600 lbs.

“We’ve used ropes and scaffolding where we’re working to remove the stones and also to reset the new stones,” he continues. By drilling holes into the old stones, the masons used a bolt with a chain, ropes, and a pulley-type system and some old-school manpower. They move the stone over to the hoist, carefully lower it down, haul it off, and then repeat the process to get the replacement in place.

This process takes a lot of work and careful consideration to get right the first time. After all, you do not get too many chances when it comes to moving and placing a 300-lb. piece of stone 40 ft. in the air. “For each piece, we have to have a game plan for how it is going to be set because there’s a lot that you just can’t lay by hand,” Madone explained. With a lot of teamwork and communication, Madone is confident that the team can do their tasks quickly, efficiently, and most importantly, safely. Other safety measures include the use of a scaffolding company rather than setting up the scaffolds internally, as well as wrapping all scaffolding in debris netting to protect both workers and pedestrians below.

As Phase One progresses, Madone is working closely with his crew, Owens Architects, and others to make important decisions on the best ways for the project to proceed. This includes the type of ties that would be used, whether or not to include additional reinforcing in the columns on the sides, and the best way to perform core drilling and stainless steel rod installation on specific pieces of stone. The team has also had to adjust their plans and remain flexible as more information becomes available as they move forward with the restoration.

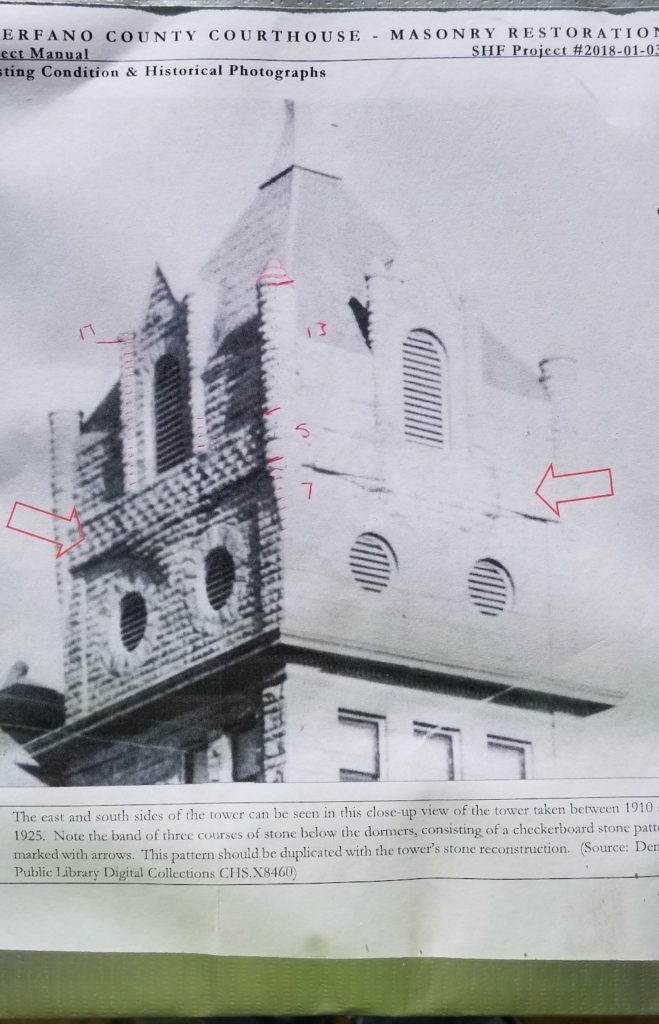

For example, the face of the building is covered with a checkerboard pattern with corbelling. When workers began with the facade, they found that it consisted of “individual 6”x6” squares, and it was originally a 24 in. piece of stone that the in-and-out pieces were carved out of,” says Madone. In fact, a lot of the stone, even the arch pieces, weren't necessarily arch keystones, most of them were two pieces with a false joint or a Hollywood joint to make one-piece look like two arch pieces. As the project progresses, there will likely be more challenges and surprises, but Madone and his team are well equipped to handle whatever the Huerfano County Courthouse restoration project has in store for them.

With a project like this one that requires a long time commitment, dedication to detail, and patience is the ultimate virtue when it comes to a successful outcome. Historic restoration and preservation projects in particular demand a unique combination of experience, knowledge, and foresight, especially when it comes to planning. “That’s one of the neat things that I like about this project,” Madone explains. “I grew up laying real stone and always wanting to work on something like this, that isn’t just a straight wall. There’s some real detail to it and we’ll bring the old world craftsmanship together with new technology to be able to do that.” Madone explains, “There is so much masonry that gets value engineered off a project,” about the common problem they routinely see. The Huerfano County Courthouse restoration is a perfect example of how important the trade is when it comes to preserving the tiny details of our history.