Tech Talk: Determining Strength Of In Place Masonry Materials

Words: Todd Fredrick

Insert fig. 1

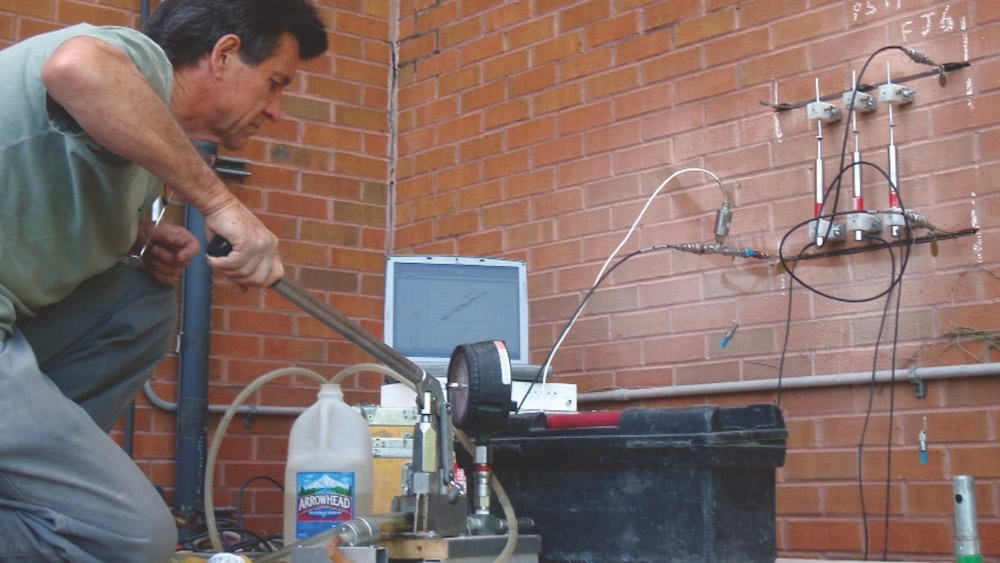

Caption: Figure 1. Laboratory compressive strength testing of a concrete block coupon.

Why would you ever need to know the strength of materials in a building that is already constructed and has been standing for years? Sometimes building use changes, and the structure is retrofitted to accommodate new tenants. This change in use may also mean a change in loads applied to the building, and structural members will have to be strengthened or added. A common example is adding a roof top deck on a building or transforming a residential space into a commercial one.

Also, as buildings age, repairs become part of the maintenance plan, and you may need to find similar materials to match the existing. If you are lucky, records and drawings of the building have been kept, and information about the materials used during construction is easy to find. If that is not the case, or if there is some doubt to the information that does exist, there are several options to determining the strength of in place masonry.

Compressive strength can be determined by sending samples to a laboratory or testing the structure in place. If you only need to know unit strength of the brick or block, samples of each can be removed from the building and sent to a laboratory for testing. For brick, whole units should be removed, while concrete block can be tested using whole units or coupons (Figure 1) taken from face shells as long as the sample has a minimum height to thickness ratio of 2:1 and length to thickness ratio of 4:1.

Remember to record where the sample came from. Keep in mind that interior brick is not always the same as exterior face brick, and units that come from highly weathered areas, such as near grade, may provide variable results. It is also not a good idea, though, to take the best looking samples for testing if the majority of units in the structure look to be in poor shape. You want to take samples from areas that are representative of the overall condition of the wall.

There are several options to find the strength of the masonry assembly. One possibility is through the unit strength method. Compressive strength of brick or block units are found as described above and if the type of mortar is known (Type M, S, or N), the masonry strength can be looked up in a table in TMS 602-16, Specification for Masonry Structures. If mortar type is unknown, it may it may be determined with a chemical mortar test which identifies the mortar constituents and aggregate to binder ratio. Estimating compressive strength using the unit strength method tends to err on the conservative side even though removing single units may be easier than taking prisms.

Another option for determining strength of the masonry assembly is by testing prisms removed from the wall. In this case, the key to getting accurate test results is making sure the prism remains intact during removal and transportation to the laboratory. Depending on the age of construction, bond between the units and mortar can be easily broken and will affect results. It is important to avoid the use of impact tools during specimen removal and to securely strap and contain the samples to avoid damaging the prism after removal and during transport. As with unit samples, take representative specimens and record the location where they are removed.

Caption: Figure 2. In situ testing of masonry compressive strength using flatjacks.

A final option for finding masonry assemblage strength is in place, also referred to as in situ, testing. If the building was built over 100 years ago, the current condition may not lend itself to reliably removing and transporting materials back to the laboratory while keeping the samples intact. Sometimes removing a large portion of the wall in order to take a sample just isn’t feasible. In this case, stainless steel hydraulic bladders called flatjacks can be inserted into the wall and pressurized to measure the stiffness and strength of the wall (Figure 2). This method requires specialized equipment and should be performed by trained personnel.

REFERENCES

ASTM C67-17, Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile

ASTM C140-17a, Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units

ASTM C1197-14, Standard Test Method for In Situ Measurement of Masonry Deformability Properties Using the Flatjack Method

ASTM C1532-12, Standard Practice for Selection, Removal, and Shipment of Manufactured Masonry Units and Masonry Specimens from Existing Construction

TMS 602-16, Specification for Masonry Structures

Words & Photos Courtesy of the MCAA